In today’s environment, there is increased attention being paid to vapor intrusion and mitigation, and rightly so. Because when volatile chemicals migrate in vapor from soil or groundwater into indoor spaces, bad things can happen.

This video addresses the problem and will give you the best solution to fix it.

Watch Video Now!

Having identified vapor intrusion on your site, the chemicals that you may discover include volatile organic compounds, such as:

-

- Trichloroethylene

- Benzene and

- Perchloroethylene

Semi volatile organic compounds might include:

-

- Naphthalene

- Elemental Mercury

- Polychlorinated Biphenyls

- Pesticides

- Or even Radon

These compounds may be naturally occurring, result from an accidental spill or from incorrect disposal methods now deemed unacceptable.

If these vapors accumulate in dwellings, they can cause severe negative health issues, safety hazards or other undesired effects. Knowingly allowing residents and workers to work and occupy those spaces may be cause for substantial financial repercussions.

A Vapor Extraction System Can Eliminate These Concerns

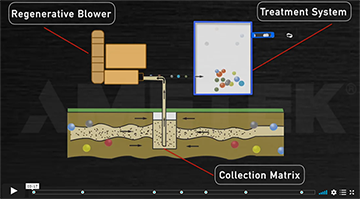

The process involves pulling a vacuum via a piping network or series of wells. The piping system or wells have a radius of influence that capture as much of the contamination zone as possible. The factors of the site will determine the optimal layout and vacuum required.

The Main Parts of a Vapor Extraction System

-

- The collection matrix can be a combination of wells drilled into the ground, perforated pipe to allow the vapor to be collected, but is most commonly a combination of the two.

- Treatment system

- The vacuum producer is the Regenerative blower.

- The collection matrix can be a combination of wells drilled into the ground, perforated pipe to allow the vapor to be collected, but is most commonly a combination of the two.

The AMETEK ROTRON Regenerative Blower is the Perfect Solution for this Application

-

- Powered by an electric motor, the ROTRON blower is made of non sparking materials.

- Made in USA

- Simple, no-maintenance design

- Rugged aluminum castings

- Chem Tough™ surface conversion (optional)

- Permanently sealed motor bearings

- Sealed construction

Which makes AMETEK ROTRON Regenerative blowers the obvious choice. When making your blower purchase decision, this application form will include all the information AMETEK needs to help you select the proper model.

To get started… you’ll need to gather some simple parameters including. . .

-

- Flow

- Vacuum

- Pressure

- Gas composition

AMETEK Dynamic Fluid Solutions is a business unit of AMETEK, Inc., a leading global manufacturer of electronic instruments and electromechanical devices with annual sales of approximately $5 billion. AMETEK Dynamic Fluid Solutions designs and manufactures a broad line of motors, blowers, fans and pumps for a variety of applications including medical, combustion, floorcare, specialized industrial and outdoor power equipment.

ABOUT FLUID TECHNOLOGY

Fluid Technology is an industrial equipment sales and engineering services company specializing in the sale and repair of mechanical equipment designed to heat and cool, filter, and move liquids and gases.